2021-11-22

——Design of gating system for aluminum alloy die casting mould

Author: Li Zelin (Senior die casting mould consultant of STRONG)

In the design of flow channel, we should not only grasp the control of liquid flow direction, but also make full use of the structural characteristics of parts to guide the liquid flow to the ideal filling state.

The details are as follows:

Material: ADC12

Average wall thickness: 2.87 (mm)

Weight: 553.6 (g)

Filling time: 0.03 (s)

Vertical projection area: 25252.1 (mm2)

Filling speed: 37 (M / s)

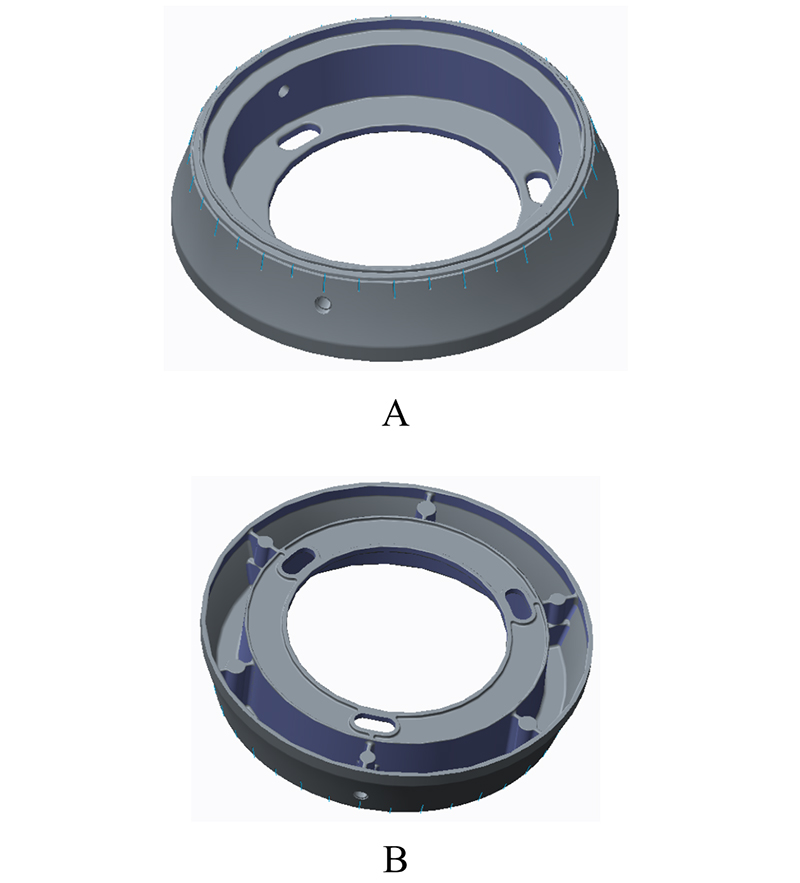

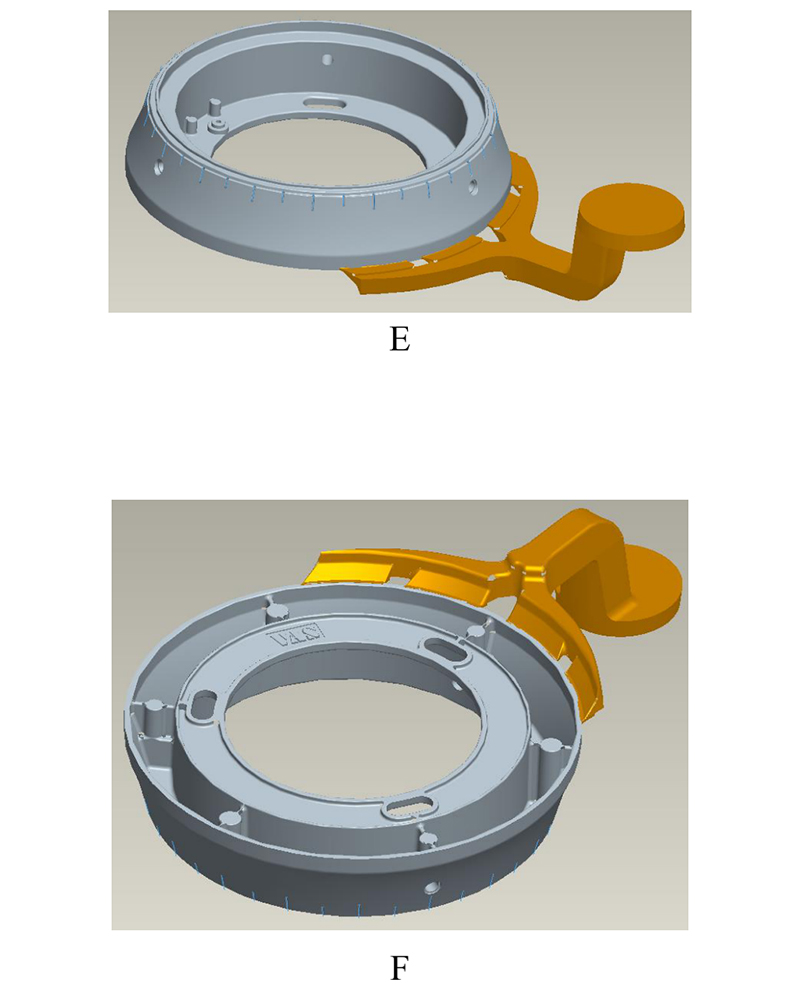

Ⅰ. features of parts

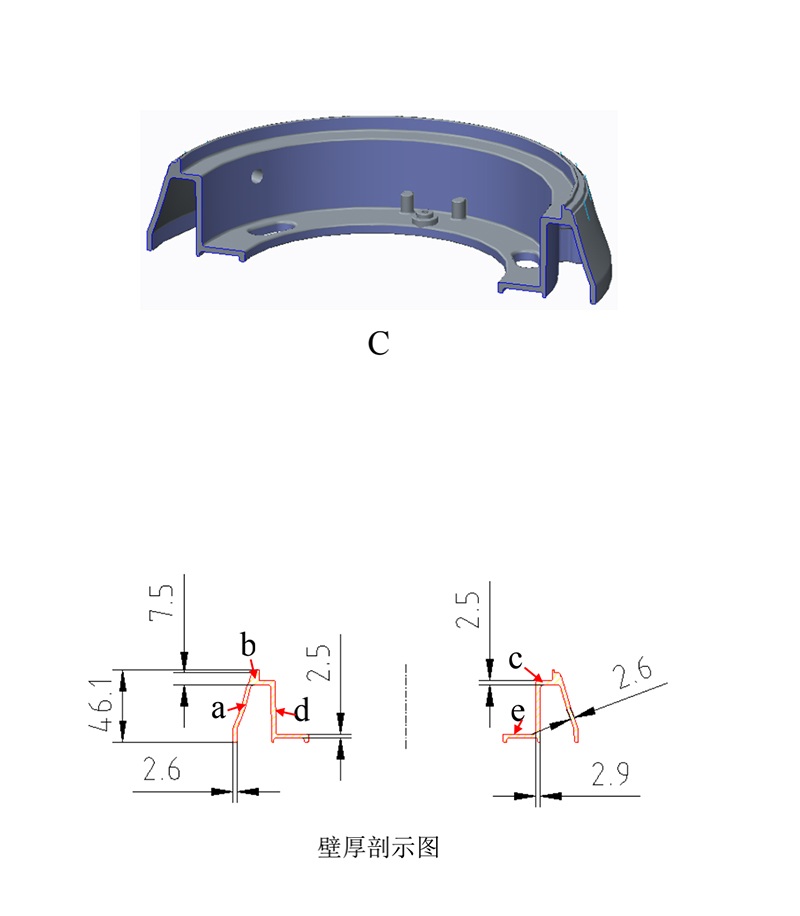

1. According to the sectional drawing of wall thickness, the liquid aluminum which is flushed upward from the bottom of surface A on surface B is a wall. Due to the obstruction of surface B, a larger part will be guided to the periphery and filled along the top of surface A. The rest of it goes down through the surface C- to the surface D and surface E.

2. Because there are three waist holes on the surface E, the surface E is divided into three parts, which need to be filled separately.

Ⅱ.Requirements for flow channel

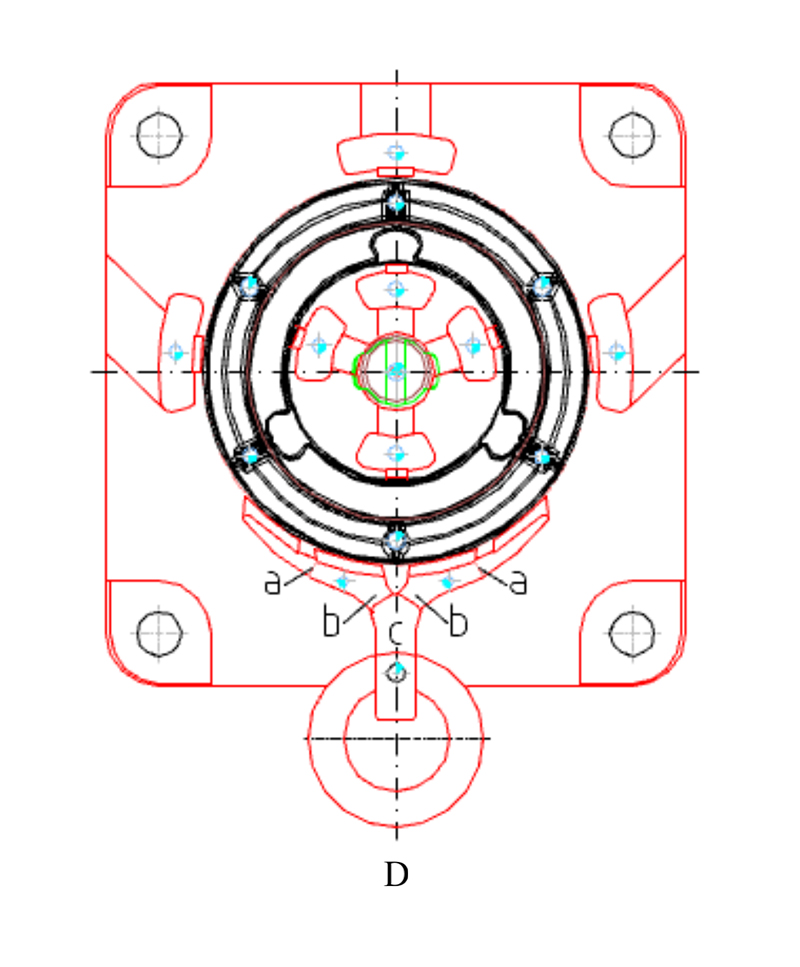

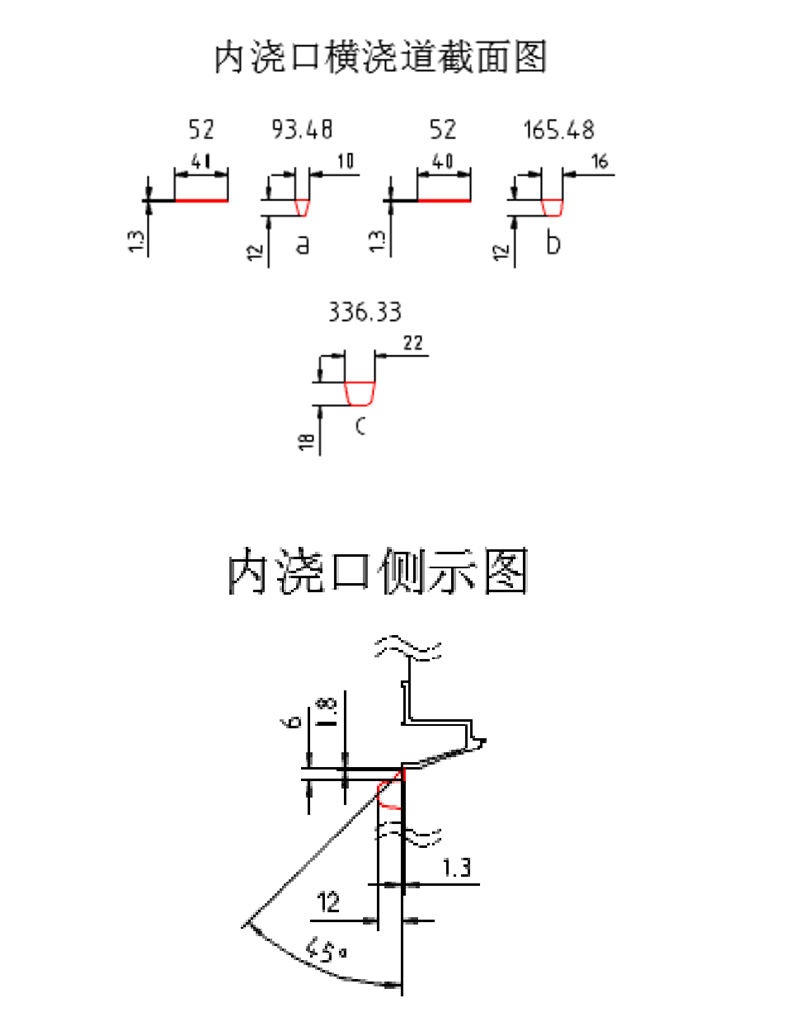

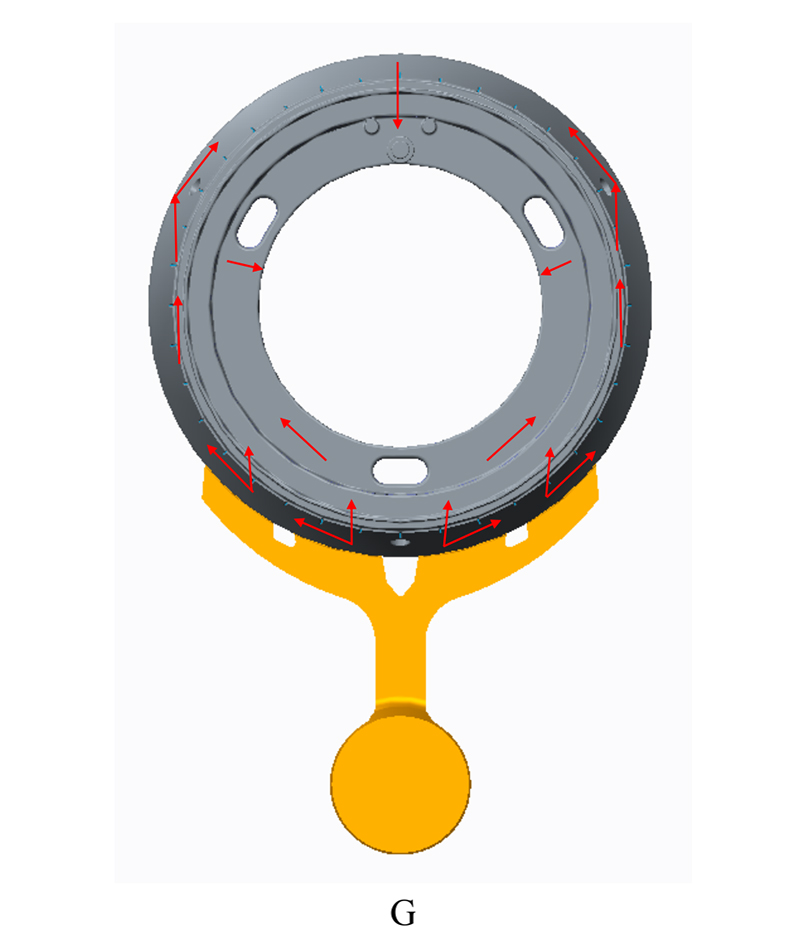

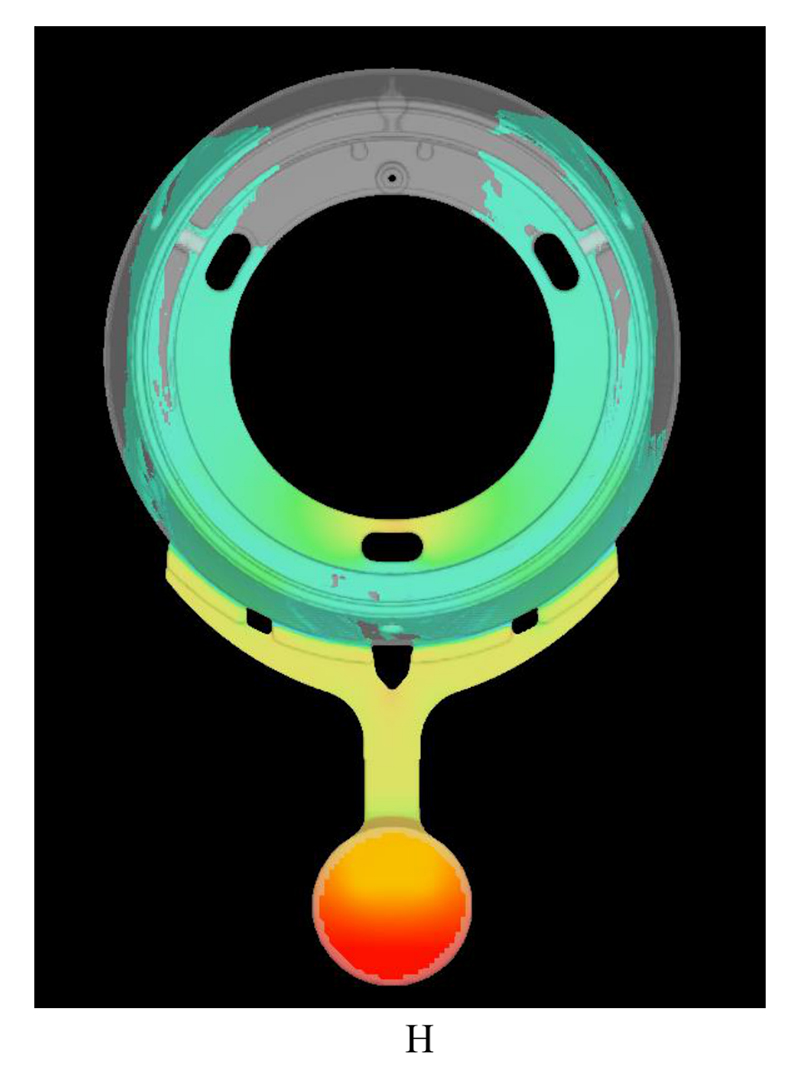

1. It can lead the liquid flow to the upper slope, and make the fluid stay at the upper part for more time as far as possible, so as to form the overall downward pressure in order to achieve the best discharge effect.

2. In order to use the cavity wall to guide, the direction of the flow channel should not point to the center of the part, but deviate from a certain angle, so as to achieve the best effect of fluid refraction. That is, when the fluid reaches the cavity wall (such as the inner sides of A and B in the wall thickness section), not only does it not refract, but it continues to move along the cavity wall until it reaches the centrifugal point. If the lower part of the periphery is filled first, the parting will be sealed, causing air trapping.

overview:

In fact, every successful case is the result of making good use of the situation. Because the shape of die-casting products is ever-changing, they have different characteristics, and their influence on liquid flow direction and flow pattern is also different. We must understand clearly, and then match with the flow channel design with a clear goal, we can make the best use of the situation.

In order to achieve a clear goal of the runner design, the designer must clearly know the direction and state of the liquid flow into the cavity? What shape does it go through in the middle? How do they affect and change the flow direction and state of the liquid? At the end, what is the flow direction and state of the liquid? Where should the exchange be? All of these should be clearly conceived in the mind of the designer, otherwise, the goal is not clear, and the simulation is only used to preliminarily verify whether there is a big deviation in the design.