2020-08-19

The life of mould is naturally related to the quality of steel. But if used improperly, even the best steel can not guarantee a good life. From heat treatment to die-casting production, temperature is one of the decisive factors of die-casting mould life.

1. Heat treatment temperature and material

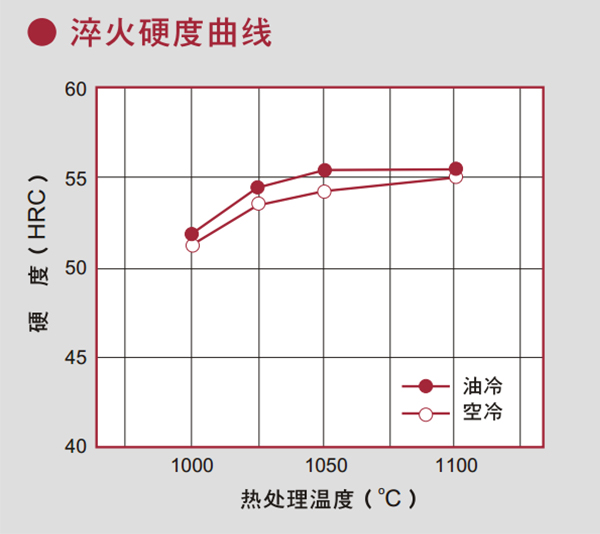

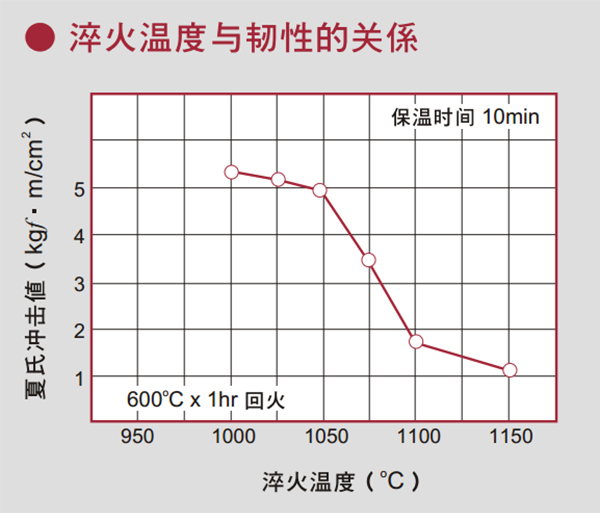

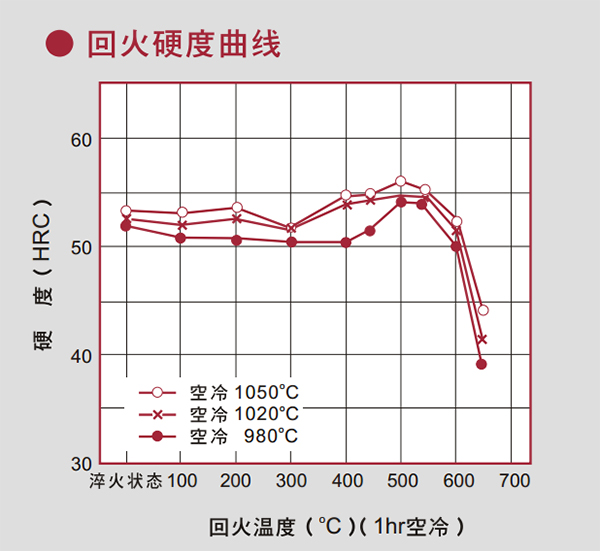

It can be seen from the above diagram that the higher the hardness required for the material, then the quenching temperature will be higher , the toughness will be lower, and the tempering temperature will be lower.

One of the important functions of tempering is to eliminate the residual stress in quenched steel. The higher the tempering temperature is, the more thoroughly the quenching stress is eliminated and the plasticity of the steel increases. Of course, the hardness of quenched steel will also decrease. Therefore, when determining the hardness of mould materials, we should not only consider raising the hardness requirement to the maximum to prevent erosion, but should fully consider the stress problem of mould structure, and reduce the appropriate hardness value according to the actual situation. Because erosion can also be solved by surface nitriding, coating, improving gating system, adjusting die casting process and so on. On the contrary, if the stress concentration, premature mould cracking and loss will be greater.

1.Temperature and material structure

In the process of heat treatment or die casting, the workpiece with sharp change of cross section or with sharp notch is easy to produce quenching crack.

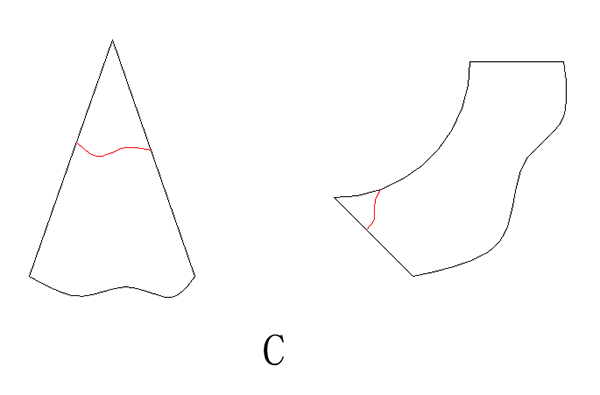

The process of heat treatment is realized by heating and cooling. The size and shape of the workpiece are different, and will affect the condition of heating and cooling.It is easy to cause stress concentration at the notch of the workpiece, and the stress value at the notch is often several times the average stress value at other cross sections. The smaller the fillet radius at the notch, the more serious the stress concentration is (as shown in Figure A、B). It is also the place where the stress concentration is most easily formed at the sharp edges and corners (as shown in Figure C). The stress concentration area can significantly reduce the plasticity of the steel, and is more likely to cause cracking and early fatigue fracture. This kind of mould structure is usually caused by the product structure. Therefore, in the early stage of product design, we should seriously consider how to avoid or reduce the stress.

The process of die casting production is also the process of heating and cooling the material repeatedly.If the temperature difference between heating and cooling is larger, the earlier the stress concentration will appear the crack and fatigue fracture.

Due to the stress, cracks appeared after 200 die casting times

2. Temperature and material properties

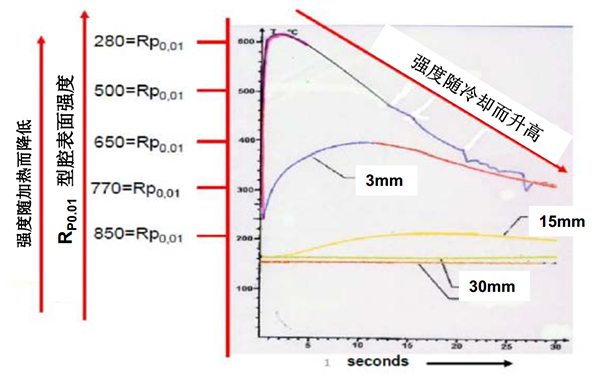

As shown in the figure above, the thermal strength of the material decreases with the increase of temperature, and even drops sharply when it reaches the critical value. In production, the temperature rise mainly comes from the flow rate of die casting liquid and the heat energy converted from filling kinetic energy. Therefore, too high temperature of material liquid and too fast filling speed will cause the thermal strength of the cavity surface to decrease, thus speeding up the erosion, mucous membrane, cracking of materials and other conditions that make the mould failure. Therefore, on the premise of ensuring the quality of die-casting products, it is an effective method to prolong the service life of mould to adopt relatively low-temperature material liquid and slow filling as far as possible.

In addition to tempering through heat treatment will completely or maximally reduce the stress generation, the resistance during production can also be reduced by filling and draining the gating system. Therefore, the design of gating system is also a temperature control technology, not to mention heat treatment. This shows how important the temperature control is to the mould life!